We specialize in all size projects.

From unique materials, to large and small CNC Machining, we do it all.

The Consistency and Precision You Need Across Every Single Part

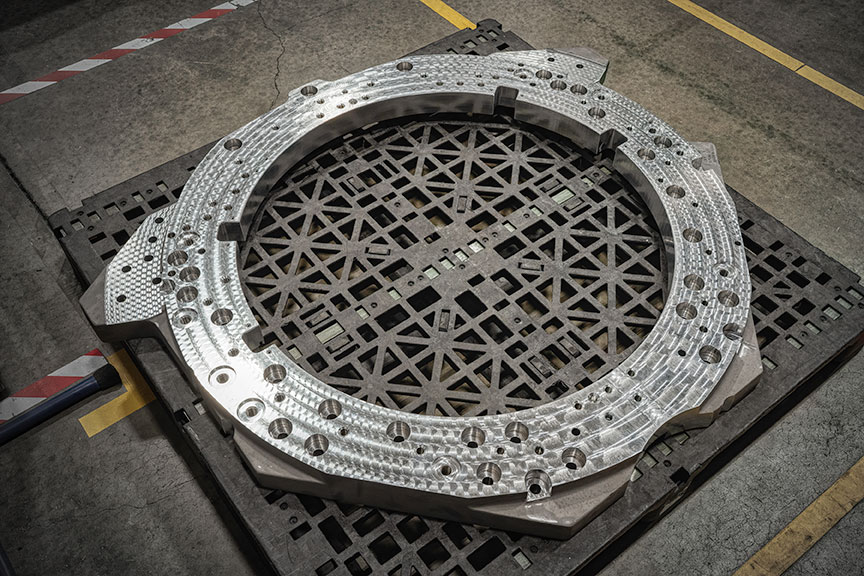

Whether you need rapid prototypes, short or full-scale production runs, Schleifring has the manufacturing equipment, assembly expertise and project management capabilities to handle your large parts machining needs. Our team consistently produces cost-effective; quality products delivered on time from our centrally located facilities in the Chicago area.

We have over 34,000 square feet of climate- and access-controlled machining space (80,000 square feet total across our two facilities), housing some of the largest CNC machines in the world with the capability to machine tight-tolerance parts up to 7 feet in diameter.

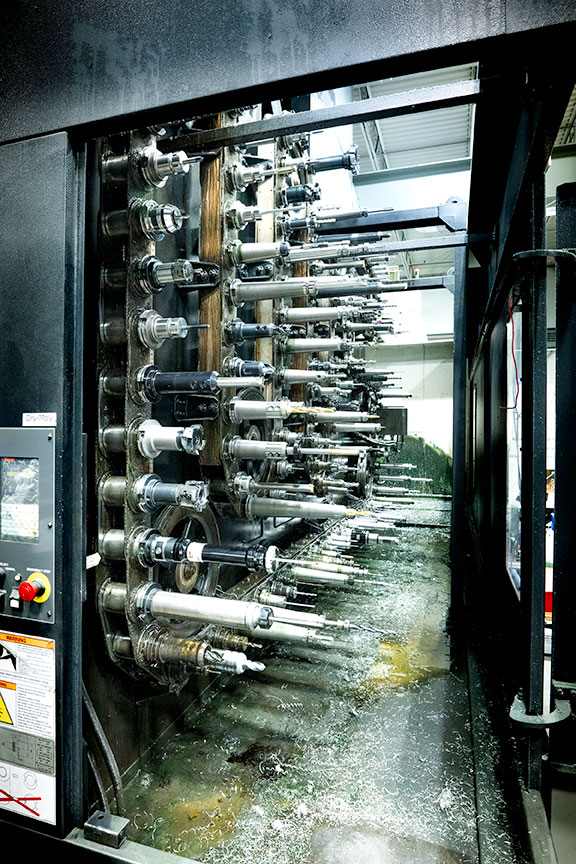

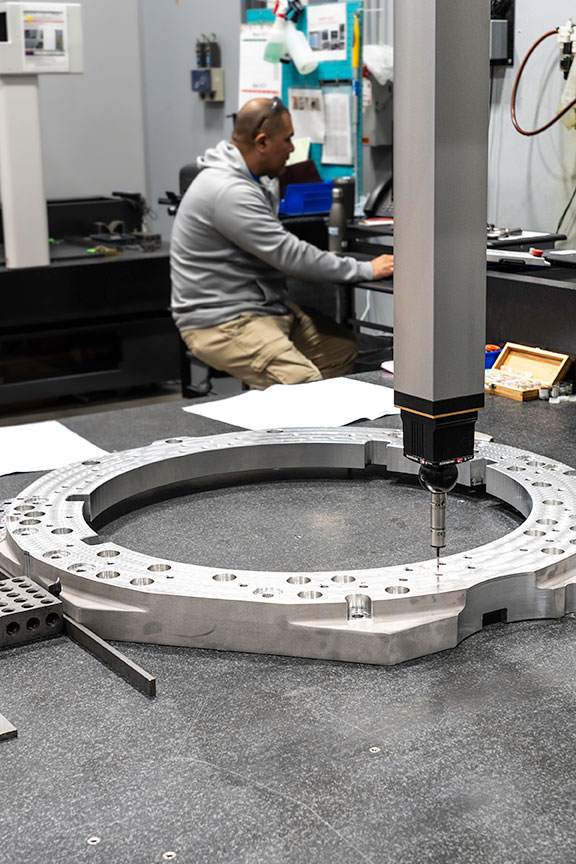

If your part features a complex design or specialty material requirement, our machines are equipped with five-axis technology to support those needs. We also offer in-house design for manufacturing support and are experienced with a broad range of materials and composites. As an ISO 9001:2015 certified company, Schleifring’s comprehensive in-house quality inspection and testing services are complemented by state-of-the-art CMMs, video measurement systems and the latest software.

Material Types

Capabilities

- 5 Axis machining

- Flexible machining

- 3-4 Axis machining

- Vertical turning

- Cross training for machine operators

- Direct Numerical Control (DNC) network

- CAD (ProE)/CAM(MasterCAM) software

- Coordinate Measuring Machine (CMM) for quality inspection

- Large tool holder capacity

Large Parts Machining

Large Part CNC Machines

Mazak e-1850V/12 II

- Handles parts up to 2350 mm (92.52″) diameter; (1800 mm) (70.87″) length

- Full 5 axis parts with 6 pallet changer

DMG DMU200 P

- X 1800 mm (70.87”); Y 2000 mm (78.7”); Z 1100 mm (43.3”)

- 5 axis machine capability

DMG DMC200 U (2 Pallet)

- X 1800 mm (70.87”); Y 2000 mm (78.7”); Z 1100 mm (43.3”)

- 5 axis machine capability

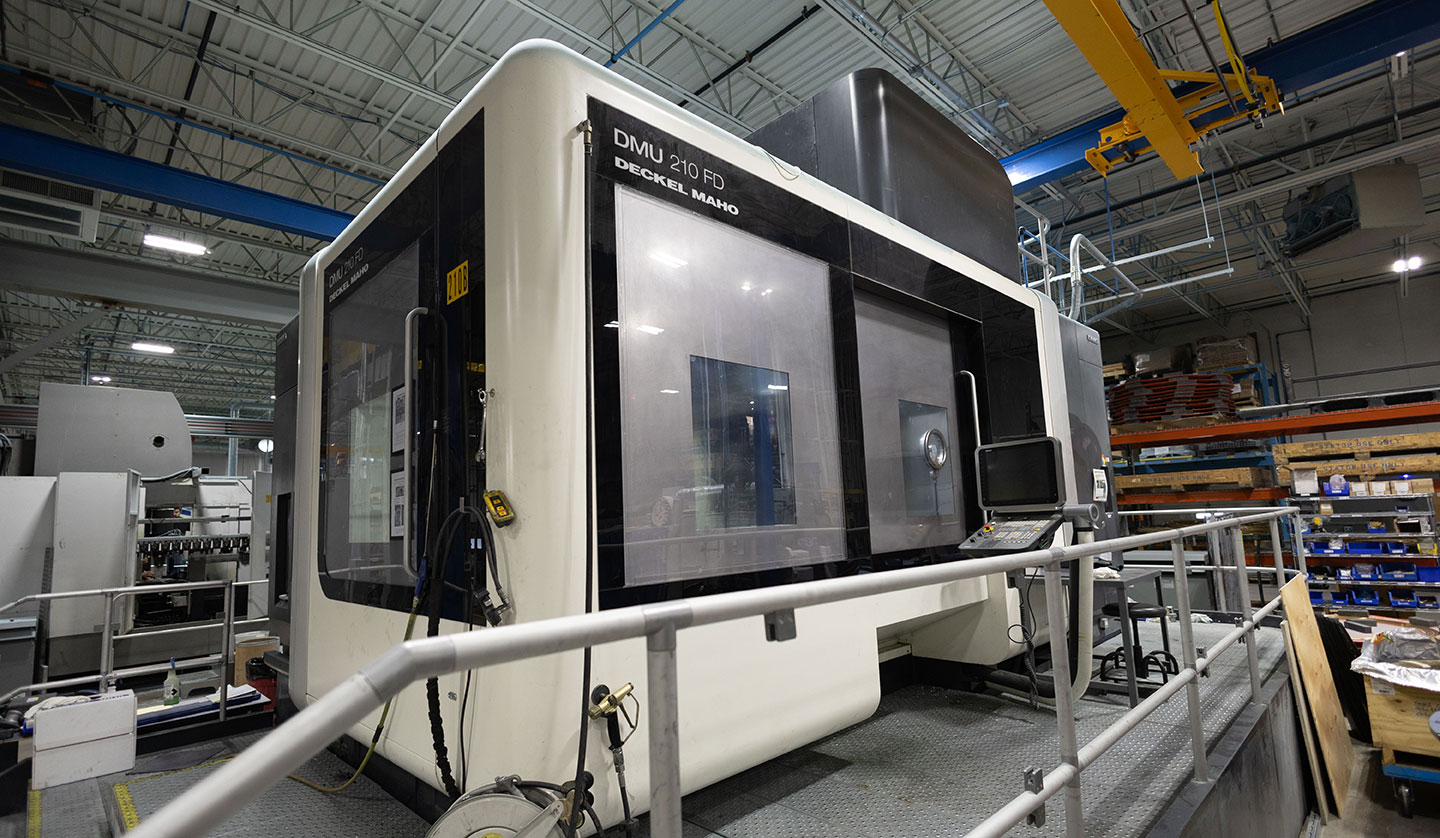

DMG DMU210 FD

- Travel: X 2100 mm (82.7”); Y 2100 mm (82.7”); Z 1250 mm (49.2”)

- Full 5 axis machine, with table rotation of 250 RPM

DMG DMU210 P

- Travel: X 2100 mm (82.7”); Y 2100 mm (82.7”); Z 1250 mm (49.2”)

- Full 5 axis machine

Wele SB316YM

- Travel: X 3060 mm (120.5”); Y 2300 mm (90.5”); Z 800 mm (31.5”)

- 5 face bridge mill

Chevalier FVM-4016DCL

- Travel: X 4100 mm (161.4”); Y 1550 mm (62.9”); Z 780 mm (33.7”)

Custom VTL (Schiess)

- 65” maximum diameter

Toshiba TUE-15

- 87” maximum diameter part

- Vertical turning center

Don’t see what you’re looking for?

Connect with us to discuss your project!